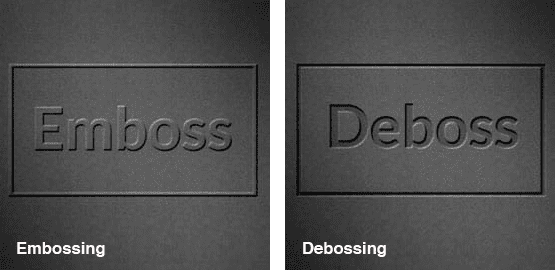

Embossing and Debossing

Embossing and debossing – two similar print effects that are sure to draw the eye!

Embossing provides your custom flyers and leaflets with a high quality, luxurious look and feel. It is often found on bespoke stationery (letterheads, certificates etc.) so will evoke quality and class.

Embossing offers a 3D effect – with a pleasant sensory feel. Debossing provides a similar aesthetic – but with a dipped area instead of a raise one.

How do we emboss your leaflets and flyers?

Your custom designed leaflets are popped between 2 metal dies. A die is like a cookie cutter – it will press in the desired shape or text. The bottom die will contain a raised version of your required design and the top die will have the same design but inverted. As the two press together, heat is applied to your bespoke flyer. This provides the embossing effect – with a permanently raised area.

Are there different types of embossed leaflet?

Yes! There are three main ways of embossing leaflets…

Blind Embossing

Blind embossing is used to describe a raised but unprinted area. This provides a noticeable but subtle contrast without the use of any ink or foil and is able to cope with fairly small detail.

Registered Embossing

This is when the embossing is used in conjunction with print, foil or spot UV varnish (or a combination of more than one of these). A second embossed area can also be used to provide even more contrast.

Combination Embossing

An image is printed, foiled or applied in spot UV and the embossing is aligned to that image so that it is stamped out. This method is particularly suited to text and simple images.

Flyer Debossing

Debossing is very similar to embossing – except the dies are reversed, meaning your design is imprinted instead of embossed. The debossing effect is very popular for custom flyers that are also invites, special offers or discount codes – as the unusual aesthetic draws the eye. Your debossed flyers can be plain or coloured, and you can add foiling to the debossed area too (learn more about foil in our foiling for print guide)!

Before creating embossed leaflets…

Artwork for embossing and debossing

Vector files are best for this process as they can easily be scaled up or down without loss of quality.

Keep it simple – embossed and debossed leaflets are already eye-catching. Don’t overload your design with too many colours and patterns. We’d suggest you keep the debossed / embossed area a single colour or foil.

Choosing the embossed area

Keep your embossed area small and to the point. We find that embossing and debossing both convey the quality of your product or service – so use them sparingly and effectively. Add embossing to your company name, event title or new product / service.

Choosing the pattern and paper weight

Consider the depth of your embossing. Deep embossing isn’t suitable for small areas as the paper will be susceptible to tearing. If multi-level embossing is to be used then use the deeper levels in the less intricate areas to minimise any distress to the paper.

Your paper will need to be thick enough to accommodate the depth without being weakened so if deep embossing is to be used then a heavy paper weight is recommended. A deep emboss onto a heavy weight paper will give a deep and detailed image.

Consider the reverse of your leaflet design

The embossing or debossing process will move the paper to the other side of the sheet so there will inevitably be a raised or recessed area on the other side of the sheet.

If you have any further questions about embossing and debossing then call us on 023 8087 8037 or email us.